About 10 years ago, people can only do international business by traveling or attending many different business fairs. 5 years ago, international business got one great step complying with the development of different online platforms.

Now, also complying with the serious situation in 2020, the international live stream is coming a new way to attract customers. Pegatec Abrasives Co. also actively participates in this surging tide of the time.

2020 is a special year. Coronavirus broke out at the beginning of this year without any vigilance and gradually spread to the whole world. China as a country having such a large population has made a lot of effort to fight against coronavirus, but still could not stop the great influence brought by the epidemic. Economics was stopped while people were fighting with viruses because people need to stay at home, especially for international trade and business. After the virus was controlled, Chinese people got one idea to keep working but stay at home or company, which is live streaming online.

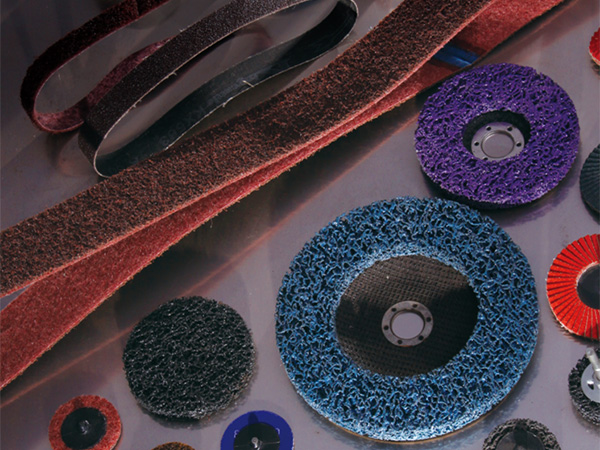

Pegatec also responds to the change of the age and actively participates in live streams in different platforms, such as live streams held by Canton Fair and Alibaba.com. Although the economy at the beginning of this year is not good, Pegatec also won many new customers through our own efforts and sales in May, June and July rose again, even more than the sales last year at the same time.

Begins on August 1, 2020, our live streams will be showed on Alibaba.com again. This time, we will move our attention to testing our cutting discs as well as discs from other companies. You will see the performance of Pegatec cutting disc directly and some interesting moments we share with you. The coolest videos, wonderful introduction, little Pegatec, direct cutting scene, these all are waiting for you. Welcome to follow our Alibaba online store to get newest promotions.

First live broadcast time: Beijing time: August 2, 2020 12:30-15:00

https://activity.alibaba.com/page/live.html?topic=3fd0a180-a418-4384-9970-5784796be32a

Second live broadcast time:Beijing time: August 4, 2020 15:00-19:00

https://activity.alibaba.com/page/live.html?topic=4243e686-5b15-4413-b9db-fa73b00bb796