Zirconium

30x20x6

- Code:PFW302006ZA

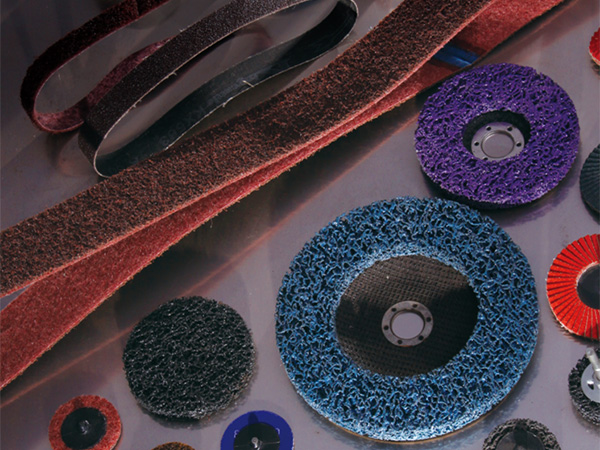

Zirconium used for steel, stainless steel, non-ferrous and flake graphite cast iron processing.

VIDEOS

-

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS -

PEGATEC IS ART

PEGATEC IS ART -

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!!

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!! -

PEGATEC serves world-class engineering

PEGATEC serves world-class engineering -

Fighting against piracy

Fighting against piracy -

Discover PEGATEC

Discover PEGATEC -

pegatec upgrade formula super awesome!

pegatec upgrade formula super awesome! -

Take a look at pegtaec's face mask

Take a look at pegtaec's face mask -

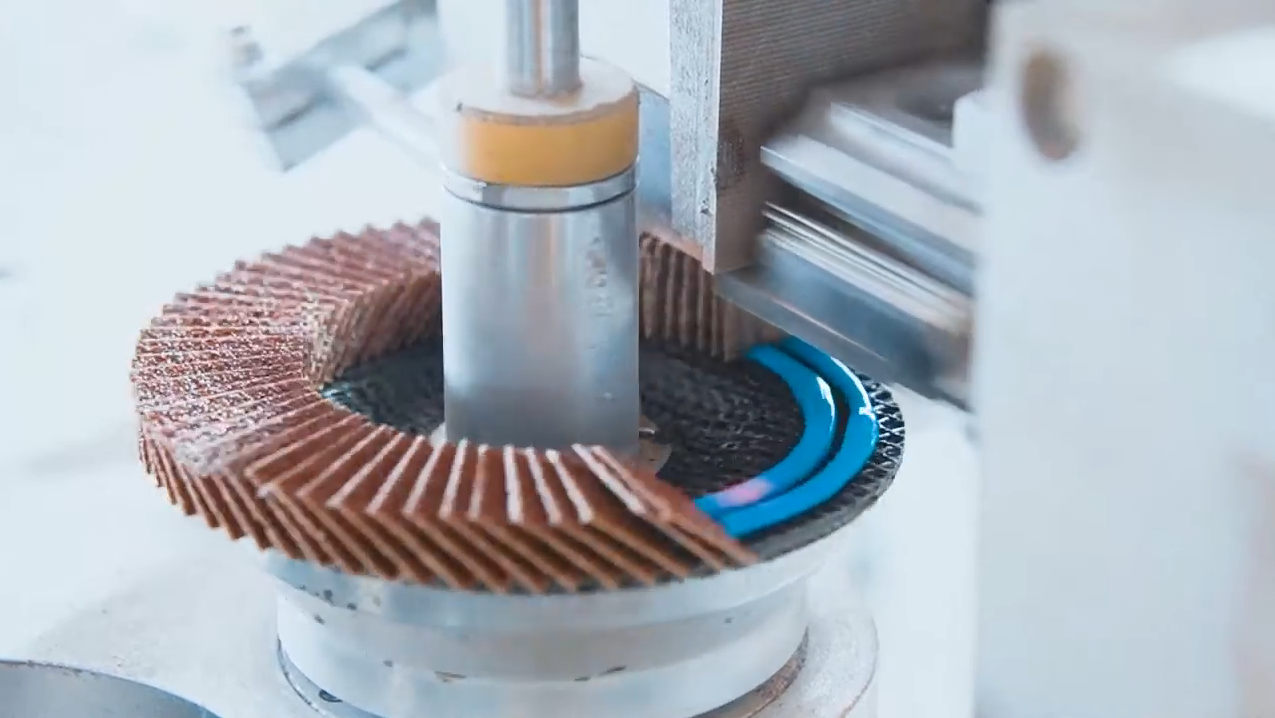

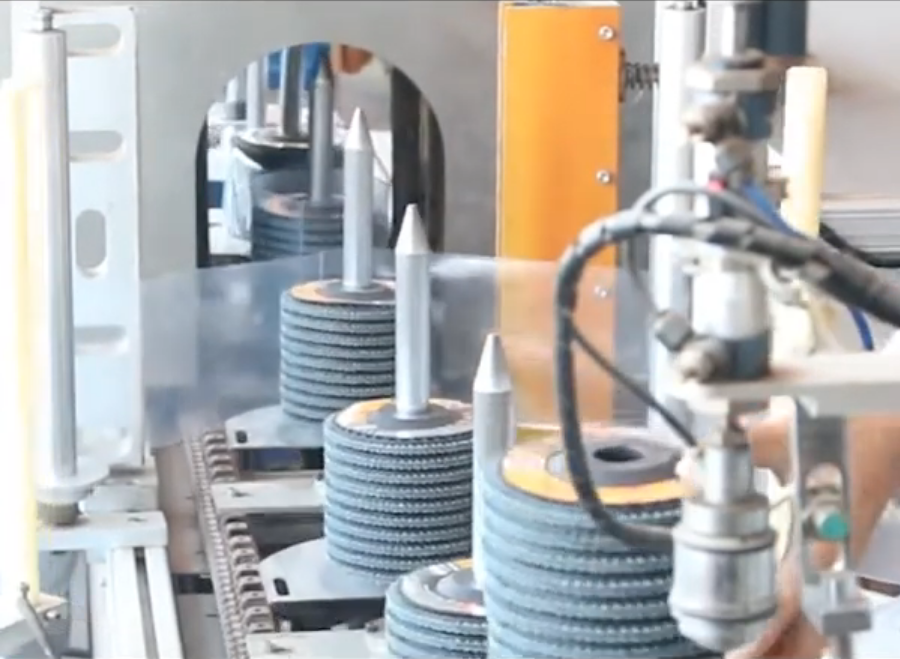

Let's find out how the flap disc is made

Let's find out how the flap disc is made -

PEGATEC ABRASIVES resume production!

PEGATEC ABRASIVES resume production! -

Why are our flap discs of good quality and high output-let's find out

Why are our flap discs of good quality and high output-let's find out -

Difference of 70m / 80m cutting disc

Difference of 70m / 80m cutting disc

Details

Zirconium used for steel, stainless steel, non-ferrous and flake graphite cast iron processing

Extra durability and efficiency

Suit to assarting grinding, get maximum grinding ratio

Avoid over load, reducing heat generation to prevent hot corrosion.

![]()

|

Product Advantages

High flexibility

High abrasive ratio brought by coated abrasive.

Even blades loss, and no residue on the work-piece.

Special structure of flap wheel with shaft makes closer working to the work-piece.

|

Application

Tools, mould and fine grinding.

Trunk, tin and difficult contact area grinding in manufacturing processing equipment.

Non-ferrous metal or light weight alloy valve and accessories precision finishing.

|

Usage Advice

Perform best grinding at 15-20m/s speed. Obtain best balance of grinding ability, surface fine finishing quality, low work-piece temperature.

Different material with corresponding grinding oil can highly increase the coated abrasives working life

|

||

|

|

|

|

|

|

|

Affecting factors of grinding |

||||

|

Tool wearing and work-piece temperature load |

|

Material grinding ratio |

|

Surface roughness |

|

Decrease grinding pressure, circular velocity and add grinding oil can low tool wearing and down temperature of work-piece |

|

To gain higher grinding ratio, suggest to use rough grit instead of increasing contacting pressure. |

|

Apply high grinding speed could gain bright and clean surface. Increasing contact pressure leads to more coarse surface. |

![]()

![]()

| Size |

Grades Available |

PCS/BOX | PCS/CTN | M/S | EAN-CODE | |

| Dia | Material | |||||

| 30x20x6 | Zirconium |

40#,60# |

10 | 300 | 80m/s | PFW302006ZA |

| 40x25x6 | 10 | 300 | 80m/s | PFW402506ZA | ||

| 50x25x6 | 10 | 300 | 80m/s | PFW502506ZA | ||

| 50x40x6 | 10 | 300 | 80m/s | PFW504006ZA | ||

| 60x30x6 | 5 | 150 | 80m/s | PFW603006ZA | ||

| 60x40x6 | 5 | 150 | 80m/s | PFW604006ZA | ||

| 80x50x6 | 5 | 150 | 80m/s | PFW805006ZA | ||