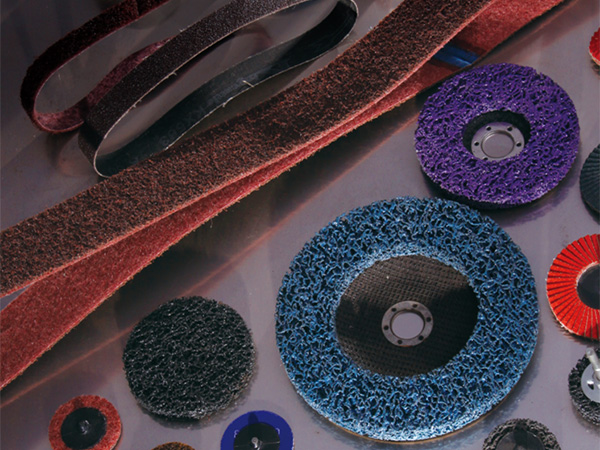

Nylon Material SPEED-FIX Discs

90x16

- Code:PSD9016A

Excellent for removal of rust, undercoating, seam-sealers and stone guards, these discs can get into hardto- reach areas like wheel wells and under carriage. Ideal for trunk beds and door jambs. Use to remove oxidation from tire rims and to remove rust from brake assemblies.

VIDEOS

-

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS -

PEGATEC IS ART

PEGATEC IS ART -

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!!

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!! -

PEGATEC serves world-class engineering

PEGATEC serves world-class engineering -

Fighting against piracy

Fighting against piracy -

Discover PEGATEC

Discover PEGATEC -

pegatec upgrade formula super awesome!

pegatec upgrade formula super awesome! -

Take a look at pegtaec's face mask

Take a look at pegtaec's face mask -

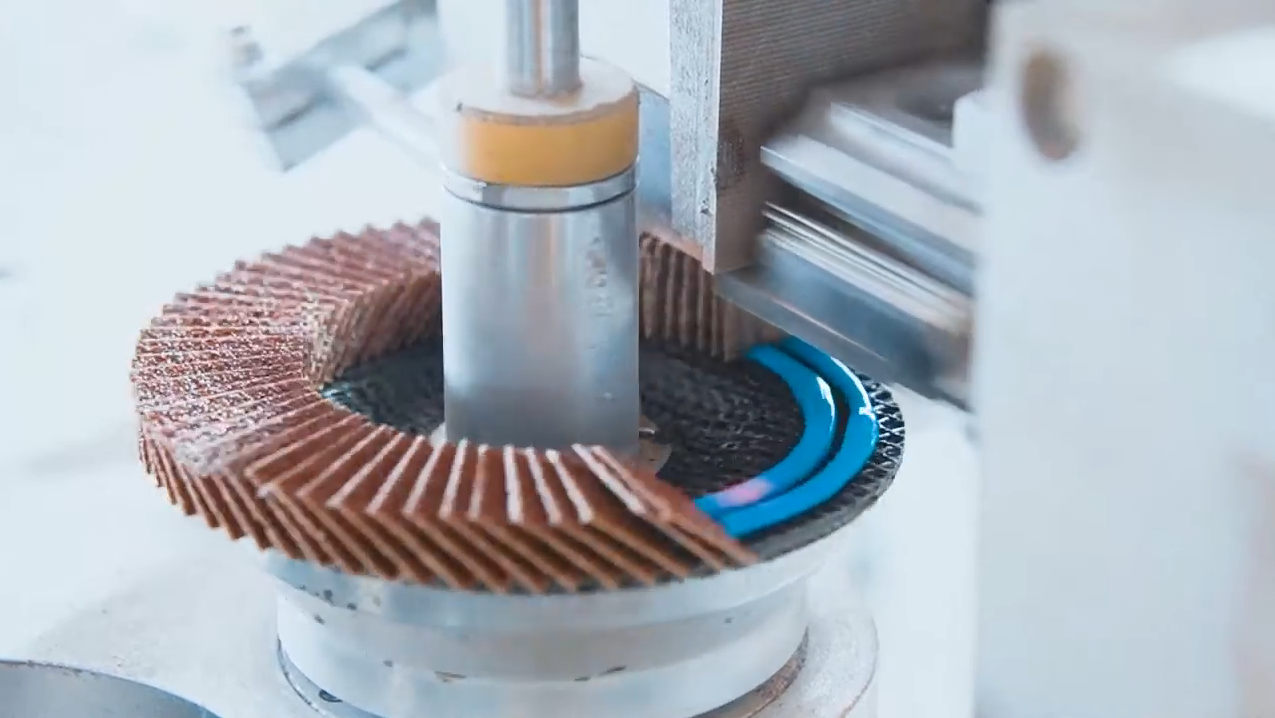

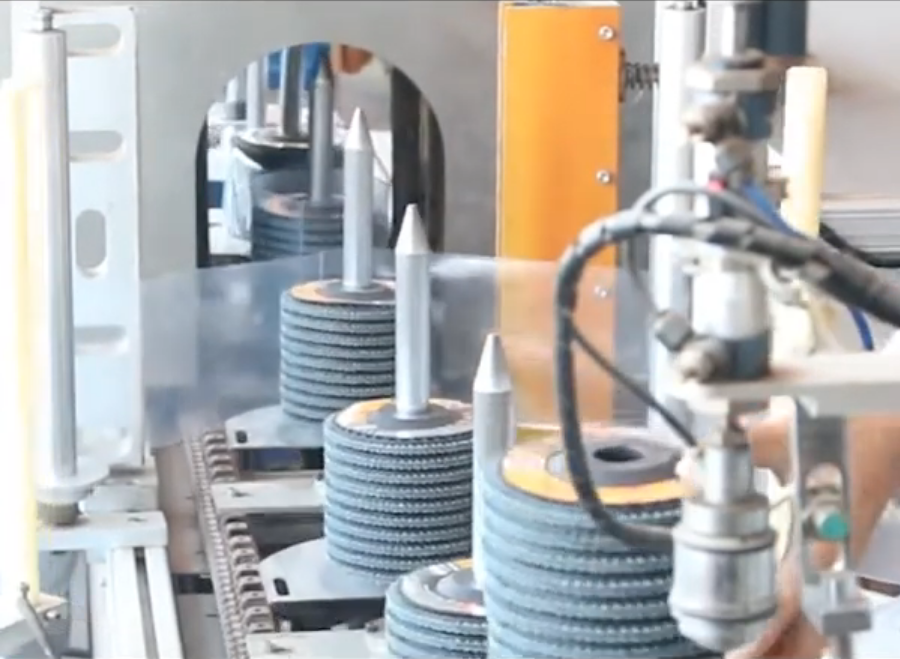

Let's find out how the flap disc is made

Let's find out how the flap disc is made -

PEGATEC ABRASIVES resume production!

PEGATEC ABRASIVES resume production! -

Why are our flap discs of good quality and high output-let's find out

Why are our flap discs of good quality and high output-let's find out -

Difference of 70m / 80m cutting disc

Difference of 70m / 80m cutting disc

Details

Excellent for removal of rust, undercoating, seam-sealers and stone guards, these discs can get into hardto- reach areas like wheel wells and under carriage. Ideal for trunk beds and door jambs. Use to remove oxidation from tire rims and to remove rust from brake assemblies.

![]()

| Product Advantages |

Application |

Usage Advice |

|||

|

Flexible structure to meet the needs of the workpiece contour and shape

Open-ended material can be prevented from clogging hot corrosion under high pressure.

Without corrosive residues on the wrokpiece surface

|

|

Removing rust, corrosion spots, dirt, stubborn paint spots, or chemical residues, old coating glue, sealant, gasket residue

Cleaning welds and blueing material, especially the blueing stainless steel surface after hot-corrosion.

Cleaning the Filler surface

|

|

Mounted wheels will achieve the best grinding performance under 15-20M / S speed, with fine surface, low temperature of the workpiece, and the best balance.

|

|

| Factors Affecting Grinding Effect | |||||

| Tool wear and workpiece temperature load | Material removal rate | Surface roughness | |||

| Reducing grinding pressure and the circumferential speed , Also adding lapping oil can reduce tool wear and workpiece overheating | To achieve higher removal rates, a more coarse grit was recommended to use ,rather than increase the contact pressure, as the pressure will cause the tool to be excessive wear and overheating | Using high operation speeds to be the more smooth surface. But to increase the contact pressure will be more coarse surface | |||

Safety Notes

To ensure safety, Please do not exceed the marked maximum speed

![]()

![]()

| Size |

Grades Available |

PCS/BOX | PCS/CTN | M/S | EAN-CODE | |

| Dia | Material | |||||

| 90x16 |

Aluminum Oxid |

Purple |

10 | 100 | 80m/s | PSD9016A |

| 100x16 | 10 | 100 | 80m/s | PSD10016A | ||

| 115x22.23 | 10 | 100 | 80m/s | PSD11522A | ||

| 125x22.23 | 10 | 100 | 80m/s | PSD12522A | ||

| 150x22.23 | 10 | 100 | 80m/s | PSD15022A | ||

| 180x22.23 | 10 | 80 | 80m/s | PSD18022A | ||

- Previous: SPINDLE MOUNTED FLAP WHEEL Connecting Shaft

- Next: None