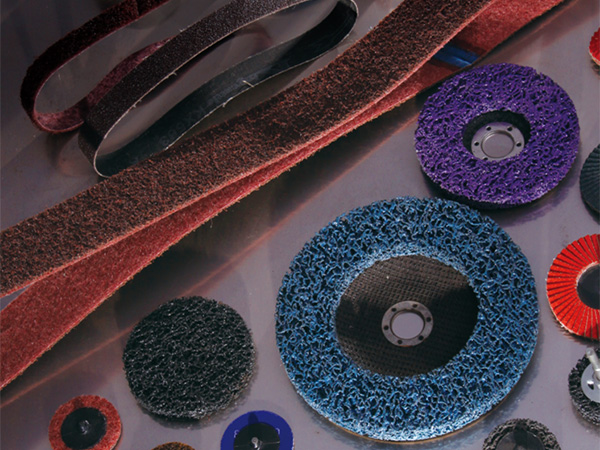

WINKING is an old-brand factory with 38 years' manufacturing experience. From 1982 to 2020, we keep continuously expanding our factory to meet the increasing demand of output.

Nowadays, after 11 years, we have built nine standard workshops on the field of 60,000 square. It proves that WINKING goes actively and successfully when meeting the challenges given by new technology and new request on factory environment.

Stable temperature, stable humidity.

New factory is divided into two workshops, which are all installed with temperature and humidity control systems. It would definitively improve the stability of semi-products.

Big enough space

Enough space could contain over 50 sets of automatic equipment, which could fulfill the demands at any time.

Automatic module.

Accurate material feeding, automatic metal ring put, automatic label absorbing, automatic disc placing… We are using the automatic modules you could image. We will reject all the inconsistency caused by the human.

Freeze

All the chemical materials would get volatilization naturally , and freeze could lower the volatilization then slow down attenuation.

120M baking equipment.

Instead of the length, What makes us feel proud of is the accurate temperature control system. Each part of equipment would adjust the temperature to have a special raising curved line basing on the different step of products for best products heating.

WINKING is continuously welcoming new changes , exploring new technology, adapting to consumer new tastes,and expanding new markets.

Now, we are the supplier of Hyundai, DAEWOO, Italian shipping yards, to offer the best solutions to those important projects.

We do believe we will lead the future.