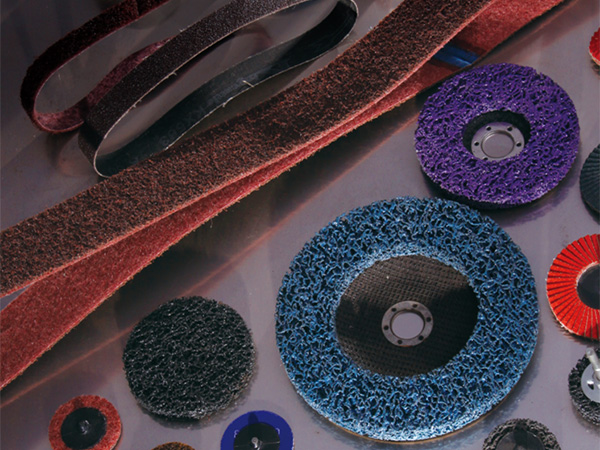

Although PEGATEC always for high requirements of quality and process.but if users choose wrong application , resulting in reduced efficiency, driving tool selected measurement errors, crisis management for using and avoid security risks.in order to solve the above problems,PEGATEC provide the following informationseller to user.Reading carefully,you will obtain more than 90% solutions.

Cutting And Grinding Recommended Practice

Arrange the workpiece so that a uniform section can be cut

Cutting Plate

Cutting Square Material

Cutting Proximate Matter

GRINDING Rough Work

Do not use a cutting-off wheel for snagging

Do not work with the side of a wheel,you will cut the reinforcing cloths

Work at angle of 10 to 30 with a longitudinal action

GRINDING Finishing Work

Angle of work 15

Rotary action

FIXED MACHINE

DOWNSTROKE HEADS

Lay out the shape parts in order to have a constant section

Avoid any wedging of the grinding wheel

Make sure the wheel is cleared

AUTOMATIC FEED

In the case of thick parts,use the

reciprocating motion of the carriage

OSCILLATING HEADS

OPERATING MODE

1 – Oscillating

2 – Cutting-off

METAL RING WITH VALIDITY DATE V=VALIDITY DATE(PRODUCTION QUARTER+3YEAR)

|

V01 | V04 | V07 | V10 |

| 1st quarter | 2nd quarter | 3nd quarter | 4nd quarter | |

|

Example: V04/2012 indicates production in the 2nd quarter of 2009 and advised usage before the 2nd quarter of 2012 |

||||