Fine Polishing Tools

Suggested Use

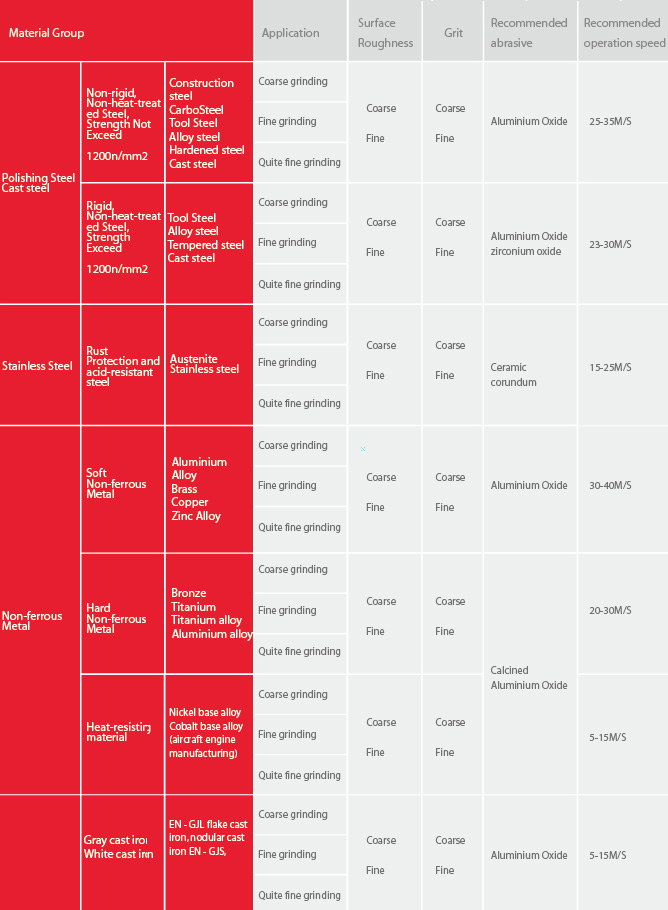

| Appliance | Recommended operation speed(M/S) |

Recommended |

| 5 10 15 20 25 30 35 40 | ||

|

Polishing Steel, Cast |

|

Page 96 |

|

Polishing stainless steel |

|

Page 95 |

|

Cast steel polishing and rough grinding |

|

Page 96 |

|

High-temperature materials’ grinding |

|

Page 95 |

|

Hard non-ferrous metal, titanium, bronze, alloy’s polishing |

|

Page 96 |

|

Soft non-ferrous metals, Brass, Pure copper, Aluminum |

|

Page 96 |

|

Hard Metal,Hard material layers,Glass,GFK |

|

Page 96 |

|

Clearance,Grinding grain operations |

|

Page 96 |

|

Polishing |

|

Page 97 |

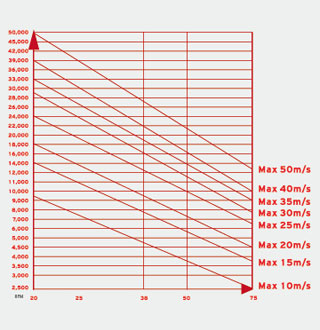

Important Operation Speed Will Affect Your Efficiency And Level Of Use

|

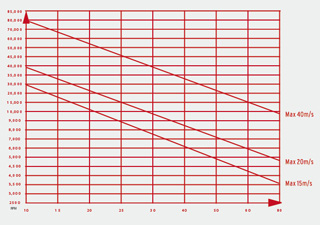

For example: Safety Notes speed,which is intersected with the vertical line of tool diameter and the given operation speed.From the intersection point , the horizontal direction corresponds to the left is the recommended speed.(R.P.M) |

The recommendation of long and short sanding belts:

Spindle Mounted Flap Wheel

|

Product Advantages |

Application |

Usage Advice |

||||||||||||||||||

|

|

|

||||||||||||||||||

Affecting factors of grinding |

||||||||||||||||||||

|

Tool wearing and work-piece |

Material grinding ratio |

Surface roughness | ||||||||||||||||||

| Decrease grinding pressure, circular velocity and add grinding oil can low tool wearing and down temperature of work-piece | To gain higher grinding ratio, suggest to use rough grit instead of increasing contacting pressure. | Apply high grinding speed could gain bright and clean surface. Increasing contact pressure leads to more coarse surface. | ||||||||||||||||||

Important Operation Speed Will Affect Your Efficiency And Level Of Use

|

Safety tips: |

| To ensure the safety, don’t over the maximum speed marked; Ensure 15MM depth of shaft jig | |

| Speed of spindle mounted flap wheel | |

| Cutting speed is expressed in diagonal. The vertical line on behalf of tool diameter intersects with given cutting speed (diagonal). From the point of intersection to the horizontal direction left is the corresponding rotate speed R.P.M. of spindle mounted flap wheel and machinery. |

| Previous | 1 | 2 | 3 | 4 | 5 | Next |