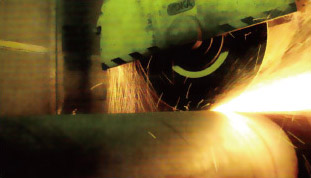

Pegatec Cutting Disc Used For Fixed Machinery Is High Performance Series,

And Skilful Is Universal Series.

|

Content |

||

|

■ Cutting technology ■ Technical information |

||

| Driving tools | Content | |

| < 3KW | PEGATEC 14“ SKILFUL 14“ |

CHOP SAW Used for cutting solid material, profile, pipe material |

| 3-5KW |

PEGATEC 14" SKILFUL 14“ |

STATIONARY MACHINES Used for cutting big solid material,and pipe material. |

| > 5KW | PEGATEC 16"14" | DESKTOP FIXED CUTTING MACHINE |

Cutting Technology

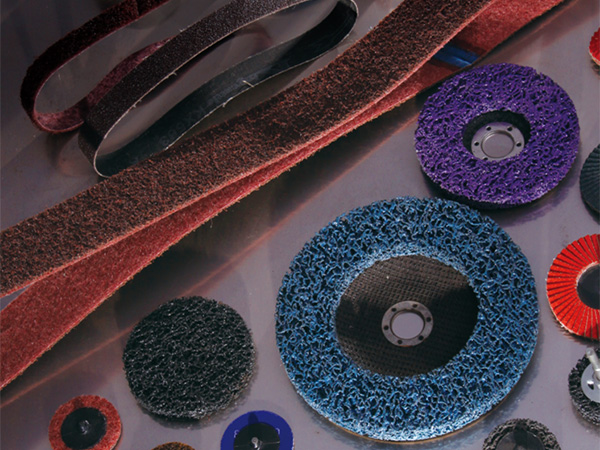

There are 4 product lines with different performance and feature. Respective direct at customer group、type of drive tools and processing task.

|

Intermittent Cutting

|

Horizontal Cutting

|

|

Swing Cutting

|

Rotating Cutting

|

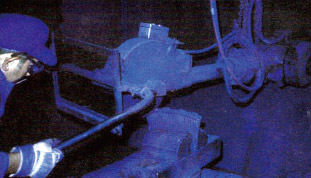

Correct Usage Of Cutting Discs

The requirement of reaching the best cutting effect is to install products correctly which is also crucial for safety. The close pictures show the aspects should be paid attention to.

.png)

| Max Speed | Color Bar | Area Using |

| 70 M/S | Asia Market | |

| 80 M/S | Europe,America,Africa, South America | |

| 100 M/S | Pneumatic Tool Market |

| Series |

Hardness grade

|

Max.speed | Attribute | Material | Market and advantage |

| TOP PEGATEC T | T | 80M/S | Hard | Steel | Europe,South-America,Middle-east |

| TOP PEGATEC T | T | 70M/S | Medium hard | Steel,Cast iron | Asia,Middle-esst Less burr on surface after cutting |

| PRO SKILFUL Q | Q | 80M/S | Medium hard | Steel,Cast iron | Asia,Middle-esst |

| PRO SKILFUL Q | Q | 70M/S | Medium hard | Steel,Cast iron |

Asia,Middle-esst Less burr on surface after cutting |

Suitable Driving Tools

| Series | Hardness grade | Max.speed | Machine Power |  |

|

TOP PEGATEC |

T | 80M/S | <3-5KW | |

|

TOP PEGATEC |

T | 70M/S | <3KW | |

|

TOP PEGATEC |

Q | 80M/S | <3-5KW | |

|

TOP PEGATEC |

Q | 70M/S | <3KW |

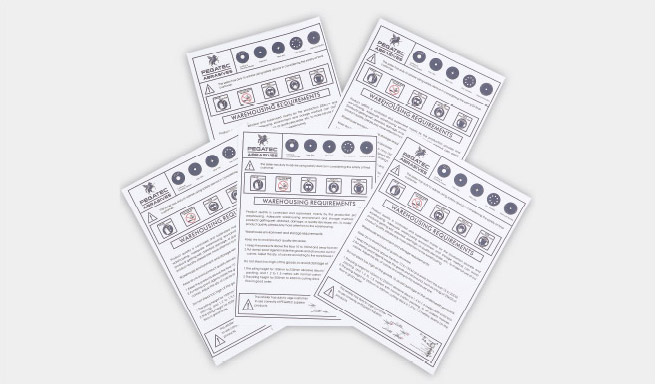

Pegatec Suggestion And Service

PEGATEC obtains a lot of experience on cutting application and usage for different work-pieces. We can offer expert suggestion once you meet any question in cutting.

| Previous | 1 | 2 | 3 | 4 | 5 | Next |